Digital twin technology is increasingly influencing sectors such as manufacturing and healthcare. By creating virtual replicas of physical assets, organizations can enhance operational efficiency and improve decision-making. In manufacturing, this leads to optimized processes and predictive maintenance. Meanwhile, healthcare benefits from tailored treatment plans based on real-time data. As industries continue to explore these applications, the implications for competitiveness and innovation are profound. The next steps in this evolution may hold even greater significance.

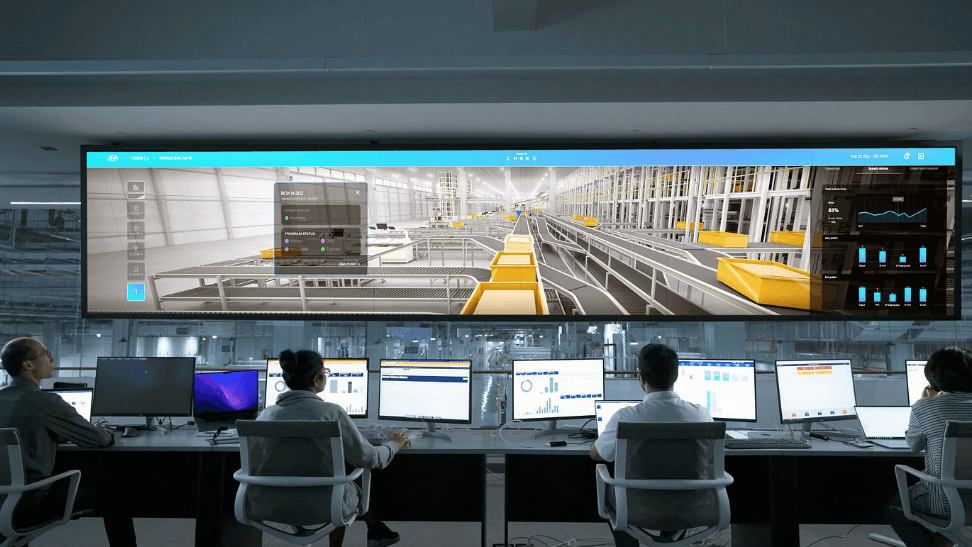

The Role of Digital Twins in Manufacturing

Digital twins have emerged as a transformative technology in the manufacturing sector, enabling companies to create virtual replicas of physical assets, processes, and systems.

This innovation facilitates process optimization by allowing real-time monitoring and analysis.

Additionally, predictive maintenance becomes feasible, as manufacturers can anticipate equipment failures and schedule maintenance proactively, ultimately enhancing productivity and reducing operational costs while fostering a more efficient production environment.

Enhancing Healthcare With Digital Twin Technology

As healthcare systems increasingly embrace technological advancements, the integration of twin technology offers significant potential for improving patient outcomes and operational efficiency.

Benefits of Implementing Digital Twins Across Industries

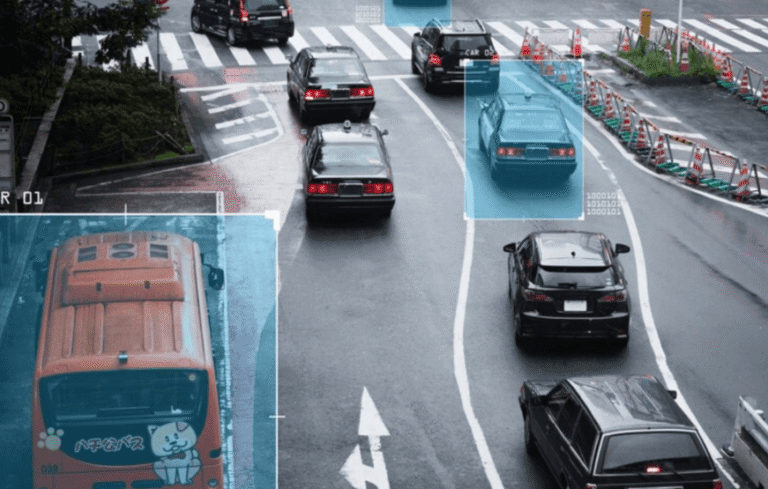

The application of digital twin technology extends beyond healthcare, offering numerous advantages across various industries.

By enabling real-time data analysis, organizations achieve significant cost savings through optimized operations.

Additionally, digital twins facilitate predictive maintenance, allowing companies to anticipate equipment failures before they occur.

This proactive approach not only enhances productivity but also contributes to sustainability efforts by reducing waste and resource consumption.

Future Trends and Innovations in Digital Twin Applications

While many industries have already begun to harness the potential of digital twin technology, emerging trends and innovations promise to further revolutionize its applications.

Enhanced predictive analytics and advanced simulation modeling are expected to enable real-time decision-making, optimizing operations and reducing costs.

As organizations integrate these advancements, digital twins will increasingly become pivotal in driving efficiency and improving outcomes across sectors.

Conclusion

In conclusion, the integration of digital twins across manufacturing and healthcare is not merely a trend; it represents a fundamental shift in operational strategy. As industries increasingly rely on data-driven insights, the theory that digital twins can significantly enhance productivity and patient care is supported by growing evidence. By embracing this technology, organizations not only improve efficiency but also position themselves to adapt to future challenges, potentially redefining standards of excellence in their respective fields.